About Screw Pilings

About

Screw Pilings

Our Story

Screw Piling Australia understands that foundations play an integral role to any building project. We provide cutting edge screw piles to simplify the construction process, whilst maintaining the highest quality engineering. We pride ourselves on the design, fabrication and delivery taking place all in-house.

We have a quick and efficient response on design for all screw piling systems, due to our in-house engineering. Our fabrication of hand-crafted screw piles are designed to suit all different site conditions, with our trained in-house engineers ensuring that we provide the best service and an accurate installation. Finally, at the end of fabrication we provide a design certification for all screw piles fabricated by our team.

Why use Screw Piles?

-

- Fast installation: The installation of screw piles is ideally a one-step process where pre-fabricated screw piles are secured into the ground. The rate is typically about 180m a day. Keep in mind that this is not affected by the presence of groundwater, and therefore de-watering is not necessary.

- Not necessary to remove soil: Since screw piles naturally displace soil as their shaft penetrates into the ground, you don’t have to pay for the soil to be removed from the site. This can be beneficial if the ground is contaminated.

- Minimal ground disturbance: With screw piles, there’s no hammering or thumping, as they use the screw action to penetrate the ground.

- Accessibility to Restricted Areas: One of the major advantages with screw piles is that they can be installed on sites with little width or headroom, where machines used for driven or bored poles can go. The more versatile equipment ensures that the screw piles can be successfully installed around other plants or structures, which essentially makes retrofitting of piles feasible.

- Incredible Earthquake Performance: Screw piles have a high ductile response and tensile strength. This is beneficial in earthquake prone zones, as piles can resist the lateral displacement and tensile forces caused by an earthquake. As they’re predominantly an end-bearing pile, the effects of negative skin friction won’t be as severe as other piling systems would. The helix does an excellent job of carrying the tension loads, so that when the soil liquefies, there will be minimum reduction in terms of capacity from the lost action of the shaft.

Note: The helix should be embedded in a sufficient depth, to reach the non-liquefiable layers so it can handle the tension loads in case of a seismic event.

- Fast installation: The installation of screw piles is ideally a one-step process where pre-fabricated screw piles are secured into the ground. The rate is typically about 180m a day. Keep in mind that this is not affected by the presence of groundwater, and therefore de-watering is not necessary.

-

- Fast installation: The installation of screw piles is ideally a one-step process where pre-fabricated screw piles are secured into the ground. The rate is typically about 180m a day. Keep in mind that this is not affected by the presence of groundwater, and therefore de-watering is not necessary.

- Not necessary to remove soil: Since screw piles naturally displace soil as their shaft penetrates into the ground, you don’t have to pay for the soil to be removed from the site. This can be beneficial if the ground is contaminated.

- Minimal ground disturbance: With screw piles, there’s no hammering or thumping, as they use the screw action to penetrate the ground.

- Accessibility to Restricted Areas: One of the major advantages with screw piles is that they can be installed on sites with little width or headroom, where machines used for driven or bored poles can go. The more versatile equipment ensures that the screw piles can be successfully installed around other plants or structures, which essentially makes retrofitting of piles feasible.

- Incredible Earthquake Performance: Screw piles have a high ductile response and tensile strength. This is beneficial in earthquake prone zones, as piles can resist the lateral displacement and tensile forces caused by an earthquake. As they’re predominantly an end-bearing pile, the effects of negative skin friction won’t be as severe as other piling systems would. The helix does an excellent job of carrying the tension loads, so that when the soil liquefies, there will be minimum reduction in terms of capacity from the lost action of the shaft.

Note: The helix should be embedded in a sufficient depth, to reach the non-liquefiable layers so it can handle the tension loads in case of a seismic event.

- Fast installation: The installation of screw piles is ideally a one-step process where pre-fabricated screw piles are secured into the ground. The rate is typically about 180m a day. Keep in mind that this is not affected by the presence of groundwater, and therefore de-watering is not necessary.

Benefits of Screw Piles

There are many benefits of screw piles over other systems including;

- Up to 20 times faster installation than driven piles

- Vibration-less

- No dewatering requirements

- Reusable and recyclable

- Suitable for all soil types

- Installed using calibrated torque correlation to soil type and strength

- No reinforcement requirements

- Simple connection to footings and structures above

- Out of ground subfloor supports

- Immediate load restraint

- Eco sensitive and minimal impact

- Nil onsite spoil

Frequently Asked Questions

Screw piles are high-grade steel shafts. Depending on the usage and ground conditions, they have a single or multiple helix to assist in penetrating the soil. The foundation piling is screwed into the earth by a hydraulic motor, until the specified load-bearing pressure for the structure is met.

When screwed into the ground, screw piles essentially cut into the soil in a constant pitch, rather than just auguring through it. The helical shafts and flights are usually manufactured in a particular way to suit specific ground conditions. When the piles reach the intended depth, they remain permanently secured in place, and the gaps are typically filled with concrete. The part left protruding on the ground provides a powerful reinforcement, where the building structure can be connected, or in some cases increase the capacity of the piles.

In comparison to a standard concrete foundation, installing screw piles takes significantly less time. It utilises less machinery, therefore becoming increasingly cost efficient. Depending on the size of the pile, a wide range of plant sizes can be used for the installation, including hand held machines. In most cases, only one machine will be required when installing a steel screw pile foundation.

Screwed piling is typically installed using a hydraulic torque drive. In order to secure a screw pile into the ground, powerful hydraulic motors are used, since they have the capacity to apply the large torques required for the installation. Typically, these motors are fastened into the handling machines, which usually come in a wide range of sizes, from 0.5T Bobcats and 20T Excavators, up to 100T crane rigs (mast mounted).

Necessary handling machines and hydraulic motors required are typically determined by:

- Torsional capacity of shaft

- Positional tolerances

- Minimum torque requirements for the installation

- Site ground and soil profile conditions

- Site access limitations

One of the most important parts of the design is the interface between the pile and the building, as it requires the utmost care. The connection is ideally designed and constructed while considering the building and the soil/ground conditions where the piles are to be screwed. This process will require a geo-technical analysis, as well as structural input from a professional.

Casting the head of screw piles into the concrete foundation of the building is the most common way of connecting a screw pile into the foundation of a structure. Rigidity is achieved by casting steel reinforcement bars into the piles, and protruding them out into the building’s footing. The reinforcing bars are generally bent at 90 degrees, and this can sometimes be substituted with Reidbar reinforcement (footplates or flange nuts screwed into the ends).

All steel will eventually corrode at some point. However, most designs take this into consideration, all high quality piles will perform for their entire lifetime. To address corrosion, consider the following:

- Surface protection should be applied onto the steel in order to limit the rate of corrosion

- Remember to allow for some sacrificial corrosion, which is the predetermined rate of corrosion in line with the accepted standards.

Managing loads of up to 100 tonne or 1000kN our screw piles are designed, manufactured and installed to effectively transfer building loads via the shaft to the helix, located at the bottom of the shaft. With high bearing and tension capacity that exceeds requirements, they are suitable for a wide range of installations; including sails, signs and wind-prone buildings.

Our unique screw pile system can reach depths of 48 metres and with low head-room clearance they are ideal for underpinning internal and under building jobs.

Installed many times faster than driven piles and suitable for all soil types, screw piles offer a cost effective and time saving solution to meet your project requirements. Vibration free and environmentally friendly, they gain further efficiency savings by making low noise and producing no spoil.

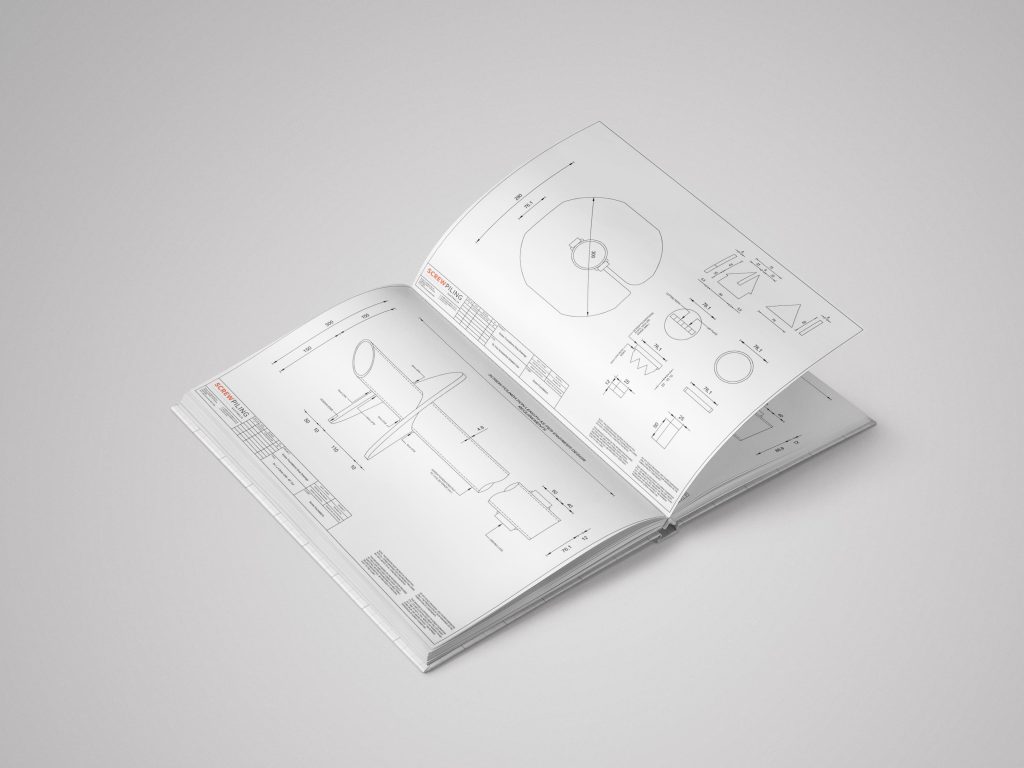

Screw Piling Specfications Guide

Would you like to know more about our Screw Pilings in detail? Contact us today and we’ll send you a copy of our Screw Piling Specifications Guide.

This guide has all our Screw Piling dimensions as per Engineer design requirements. Contact us today!